SOKEN ELECTRIC CO., LTD.는 창업이래 산업 기기용의 측정기 메이커로서 전기 기계, 송배전 기기, 가전제품, 전기절연재료 등의 설계 개발, 품질 보증에 크게 공헌해 왔습니다. 또 측정 기술의 노하우를 살려 전기 절연 진단 분야에도 진출해, 플랜트 maintenance 분야에 있어 더욱 더 그 쉐어를 확대하고 있습니다.

더욱이 그년의 산업구조의 변혁, 다양화에 유연하게 추종 해, SOKEN ELECTRIC 제품의 응용범위가 지금은 자동차 산업, 반도체 산업에 까지 치닫고 있습니다.

SOKEN ELECTRIC CO., LTD. 는 앞으로도 개발 지향의 측정기 메이커로서 산업계 전반에 걸쳐 다양한 요구에 응답하면서 약진을 계속해 갈 것 입니다.

MAIN PRODUCTS

What is Partial Discharge?

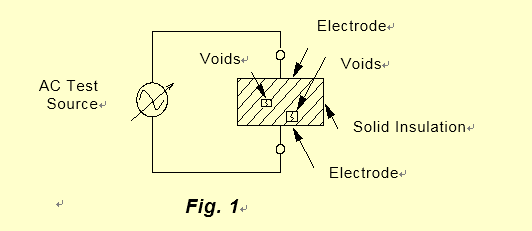

Fig.1 is a general partial discharge occurrence model, and showing an insulation sandwiched by electrodes. In the insulation, there are voids (impurities).

Dielectric constant of the voids is usually lower than that in the surrounding dielectric. Therefore when AC voltage is applied to the insulation, voltage in the voids becomes larger, and as a result, the voids short itself out, while the insulations is not shorted.

The short circuit in the voids leads to small charge-transfers, and this is called partial discharge.

Why is Partial Discharge Test Important?

Even with a stringent manufacturing process, it is not always possible to manufacture solid insulations without creating voids (impurities).

Generally, the void in solid insulation is filled with a gas, and it has lower breakdown strength than the main material. In addition, the permittivity of the void is invariably lower than that of main insulation, and electric field tends to concentrate on the void. Thus, even under normal working stress, the voltage across the void may exceed the breakdown value and partial discharge occurs.

When partial discharge begins and repeats, it can damage the materials and may lead to failure of the whole high voltage power equipment. To secure safety of electrical appliances, quality of insulations must be regarded as the most important matter.

Partial discharge measurements are desirable test to find insulation defects and early failures in insulation materials. Periodic diagnosis enhances safety of electrical appliances, and can help to find symptoms before becoming a failure.